Tungsten Carbide CNC Cutting Tools

Tungsten Carbide CNC Cutting Tools

Wey Juan Technology Co., Ltd. was established in 2000 and built the brand WEY JUAN. It mainly produces various different tungsten carbide cutting tools such as end mills, drill bits, and reamers. In addition, we sell tool holders, collets and spare parts to professionally serve the customers in Taiwan, Europe, Asia, South America, North America, South Africa, Australia and other countries. Moreover, we provide OEM services for foreign brands.

Provide solutions for various industries

Wey Juan tungsten carbide end mills can be used for high hardness, high speed machining and cutting of soft metals as well as steel, cast iron, alloys, stainless steel, titanium alloy, nickel, superalloys, hardened iron, copper, and aluminum alloys, etc. Wey Juan end mills can be used in a variety of industries, such as molds, machinery and electronic hardware parts, automobiles and motorcycles, semiconductors, aerospace, optical and optoelectronics industry, sports equipment, biotechnology and medical industry and other industries that require high precision CNC machining.

Advanced production technology

Rigorous quality control system

Rigorous quality control system

After years of efforts, "Wey Juan" has become the famous brand in the industry and one of the major suppliers in the end mills market. Wey Juan uses tungsten carbide rods imported from Germany and Japan, and grinds them with "TTB&ROLLOMATIC" machines from Germany and Switzerland. From materials to goods, we have set up various quality inspection standards and measurement systems in order to provide customers with more accurate inspection reports. We use German measuring instrument ZOLLER to measure all aspects of the tools to ensure the consistency of the quality of each product. In addition, our R&D team is dedicated to the testing of all kinds of tools to ensure the quality and service life of the tools.

Customized Service

In addition to manufacturing standardized tools used in the market, Wey Juan specializes in the customization of various types of forming tools. We provide customers with customized tools consulting services and produce customized tools according to the machining needs of different industries. The smallest diameter of the end mills can reach 0.1 mm, and the highest hardness can be up to HRC 68.

With high quality, sufficient stock and competitive price, Wey Juan tungsten carbide end mills can definitely meet your needs.

With high quality, sufficient stock and competitive price, Wey Juan tungsten carbide end mills can definitely meet your needs.

Tools Production Process

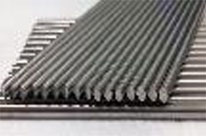

Step 1Materials used

High quality tungsten carbide rods imported from Germany and Japan.

Step 2Tools Manufacturing

Length Cutting

Cutting tools to the length required by the customer.

Polishing of rods.

The round rod is polished.

Pre-machining

Before grinding the forming end mill, the polished rods should be processed into semi-finished products such as spheres, segments differential, effective length or other forming tools as required.

Tool Forming and Grinding

We use German and Swiss TTB & ROLLOMATIC high-precision digitally controlled grinding and cutting equipment to grind tools.

Step 3Coating treatment

According to the different needs of customers, a variety of coating options are provided.

Step 4Quality inspection

All-round measurement of tools with ZOLLER from Germany.

Step 5Packaging

The qualified end mill will be put into the tool box with WJ’s logo, model number and specification sticker on the outside of the box.